WARSHIELD® Protection Mesh (Rockshield)

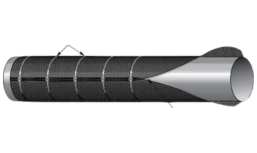

Longitudinal Wrapping

For pipes with a circumference of less than 150 mm (6”) in relation to the width of the WARSHIELD™ Plastic Net:

1. Unroll the mesh parallel to the pipe which is to be protected.

2. Place the mesh below the pipe.

3. Wrap the mesh around the pipe, overlapping the edges by approximately 150 mm (6”).

4. The mesh can be secured using plastic straps or can be heat bonded by using a gas torch and pressing the two surfaces together.

Latitudinal Wrapping

For pipes with a larger circumference than the roll width:

1. Cut the mesh into pieces 100–150 mm (4–6 inches) extra than the circumference of the pipe.

2. Wrap the pipe with the mesh, overlapping the adjacent installed mesh by 150 mm (6”).

3. Fix the mesh with plastic straps or heat bond the longitudinal joint using a gas torch and pressing the two surfaces together.

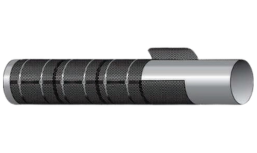

Spiral Wrapping

This process can be applied to larger circumference pipes:

1. Start wrapping the pipe, moving along the length of the pipe so that the mesh overlaps slightly.

2. Use plastic strapping to secure the mesh as it is wrapped.